It is the picosecond freckle removal and myopia correction we use in medical cosmetology. Picosecond freckle removal is a relatively advanced freckle removal method at present. The picosecond laser in the United States is a laser with a peak power of 3 watts. The picosecond laser used in industry is The infrared picosecond laser with a power of 30-100 watts is dozens of times more powerful than the laser used in medical aesthetics.

Infrared picosecond laser has high pulse energy, long service life, efficient and fast work, and can realize marking, drilling, cutting, etc. For micron-level processing requirements, it can also obtain fine and clean cuts and minimize thermal impact. It is Modern industrial micro-machining tool. For various materials: film cutting, ceramic drilling, metal blackening, glass cutting, plastic marking, etc., and are widely used in all walks of life.

Micro machining marking

The infrared picosecond laser shows great advantages due to its extremely narrow pulse width. It uses the characteristics of low heat energy diffusion to perform better than other lasers in processes such as metal blackening, plastic marking, and glass paint stripping. In the laser engraving effects of different lasers on metal aluminum foil, it can be seen that the contrast of the picosecond infrared marking effect is more obvious and the marking is clearer.

stripping paint,

Due to its negligible thermal impact, the infrared picosecond laser will cause almost no damage to the base material during the paint stripping process, especially glass and plastic materials. The paint stripping quality is good and the base material has no texture.

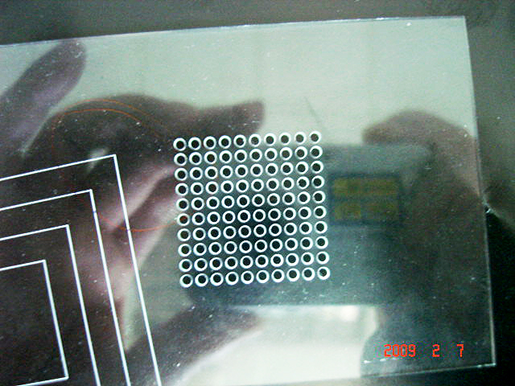

cutting drilling

Infrared picosecond laser can cut many materials, such as stainless steel, carbon steel, copper, aluminum, magnesium alloy glass, etc., and is used in mobile phones, 3C electronic chips, FPC, solar energy and other fields. But the most outstanding performance is the drilling and cutting of glass, which can achieve vertical cutting and drilling without tapered holes.

The non-contact processing of infrared picosecond laser can also avoid problems such as edge chipping and cracking that are prone to occur in traditional machine cutting methods. It has high precision, no micro-cracks, broken or fragmented problems, high edge crack resistance, and no need for washing or polishing. , polishing and other secondary manufacturing costs and other advantages, while reducing costs, it greatly improves the workpiece yield and processing efficiency.