In early 2013, a company in Huizhou specialized in producing eardrums for mobile phone receivers (referred to as sound membranes) for South Korea's Samsung. The sound membrane is the diaphragm used for speaker playback. In earpiece speakers and dome speakers, for the convenience of assembly, the dome membrane and the voice coil are often bonded together to form a component.

In the traditional production line: hundreds of small die-cutting machines are distributed in the workshop, one die-cutting machine for each person, and the employees repeat a mechanical die-cutting action like a robot. Each worker can die-cut about 30,000 sound films per shift. , high labor intensity and high risk (hand die cutting), especially due to factors such as "the difficulty of recruiting ordinary workers" and "rising labor prices". Factory owners urgently need to "replace people with machines" to change the current decline in product prices faced by the factory. , the dilemma of rising costs...

According to an acquaintance, after we went to the factory workshop for on-site inspection, after working day and night, the R&D team overcame various technical difficulties and finally successfully developed the "sound film laser cutting machine". Since then, the "sound film laser cutting machine" has appeared in the industry. Key words.

The special sound film laser cutting machine consists of two major structures: the mechanism operating part and the laser component. The two major structures are controlled by computers and special software to achieve high-speed and precise cutting of the sound film, and are equipped with a specially developed "sound film automatic Packing Machine".

Equipment operating mechanism: It adopts a marble base and is equipped with precision linear guide rails and ball screw modules to ensure the stability of high-speed operation of the XY axis. According to the different materials and specifications of the sound film, molds matching the sound film specifications are prefabricated and fixed. on the operating mechanism.

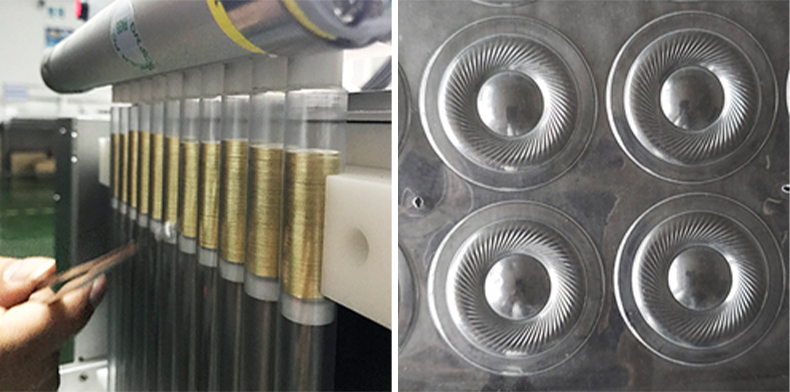

The picture on the left is a sound film laser cutting machine

The picture on the right is a sound film automatic packaging machine

Laser working system: including laser, power supply, beam expander, cutting nozzle, air pressure, dust exhaust, deodorization and exhaust, etc. The upgraded version also includes high-speed laser galvanometer. The picture on the right is the matching sound film packaging machine.

After the laser cutting of the entire sound film is completed, place the entire sound film on the packaging machine platform. The machine will automatically grab each sound film and quickly and accurately place it into the corresponding packaging box. When the box is full, the equipment will automatically stop. and beeps to remind.

After the "machine replacement" in the workshop, each person was on duty for 4 pieces of equipment every day, and the output reached more than 100,000 pieces. The production efficiency was greatly improved, and the excellent rate increased to 98%. The special sound film laser cutting machine has since gained unanimous recognition from customers and the market. Good reviews.